Water Recover & Recycling

Advantages

- No heat generation and rejection units.

- No chemical treatment in process

- No use of membrane, reverse osmosis

- No membrane disposal issue resulting elimination of the plastic by in large

- Complete process of evaporation is at "Low Temperature”

- Direct wastewater to clean water in single step

- Condensate is in purest form so no/less extraction of the ground water

-

Continuous use of condensate in process ease the process parameters as well keep descale most of time the complete lines and plant & machinery

- Most effective water balance, water management solution

-

High life cycle evaporator because of the stainless steel construction

Compact and minimal footprint area - Robust and fully automatic

- Lowest electricity demand

Upto

99%

Water Recovery & Recycling

Low Temperature

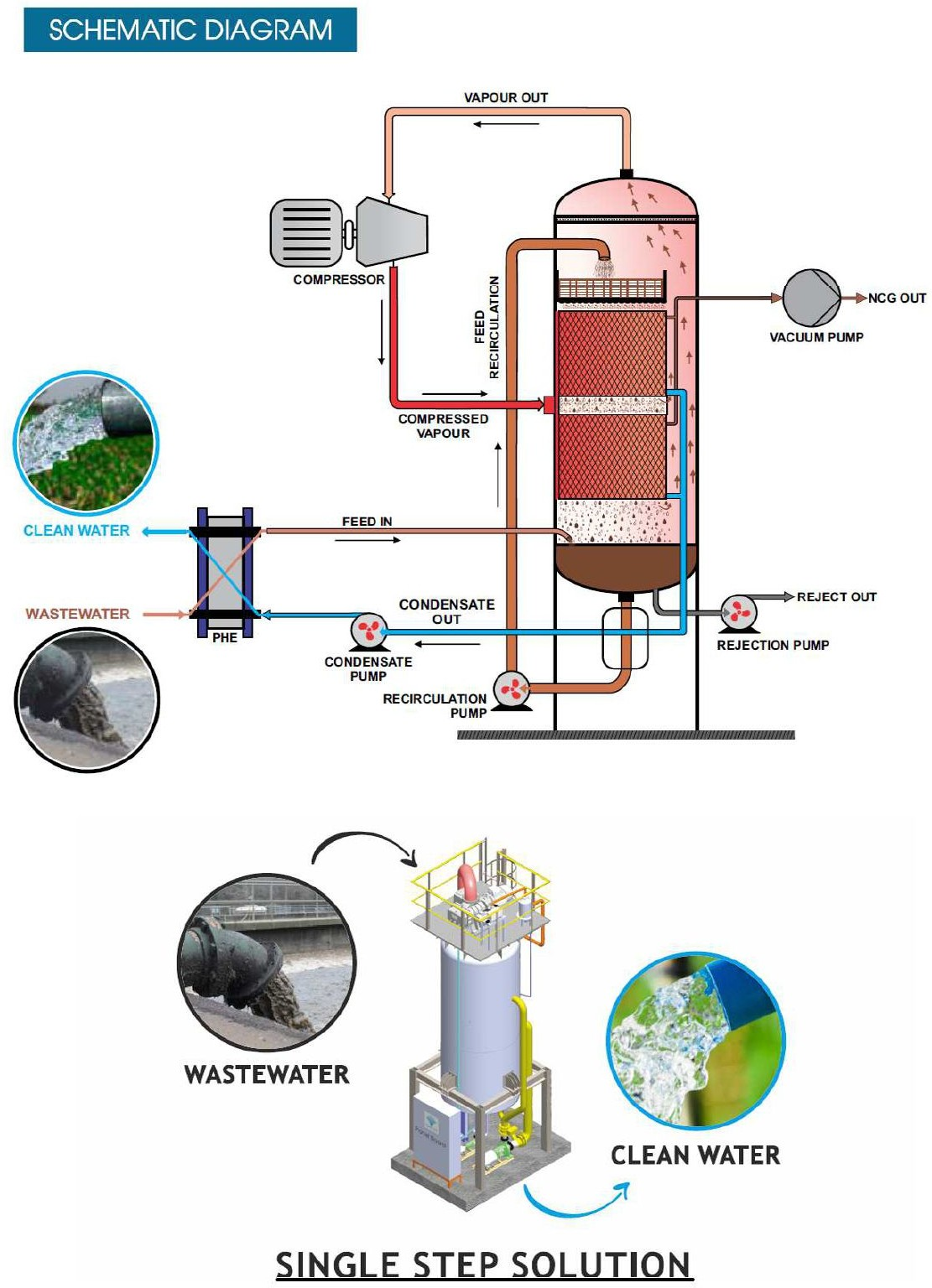

Evaporator Module (LTEM)

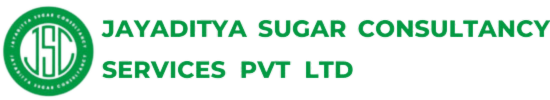

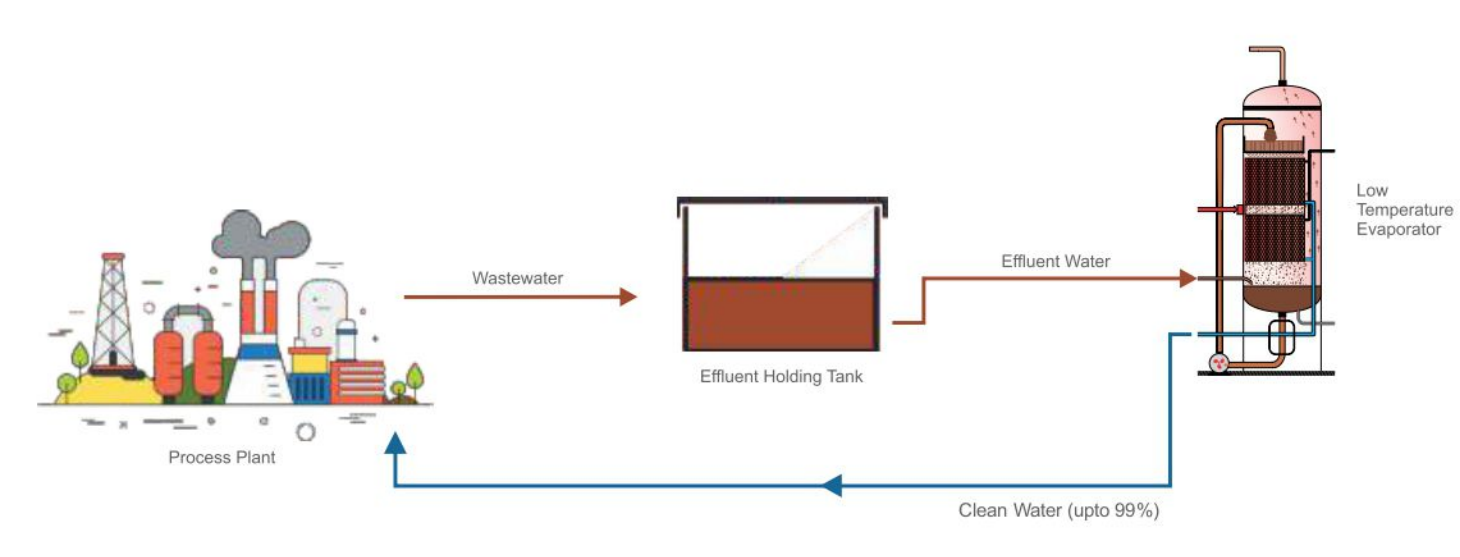

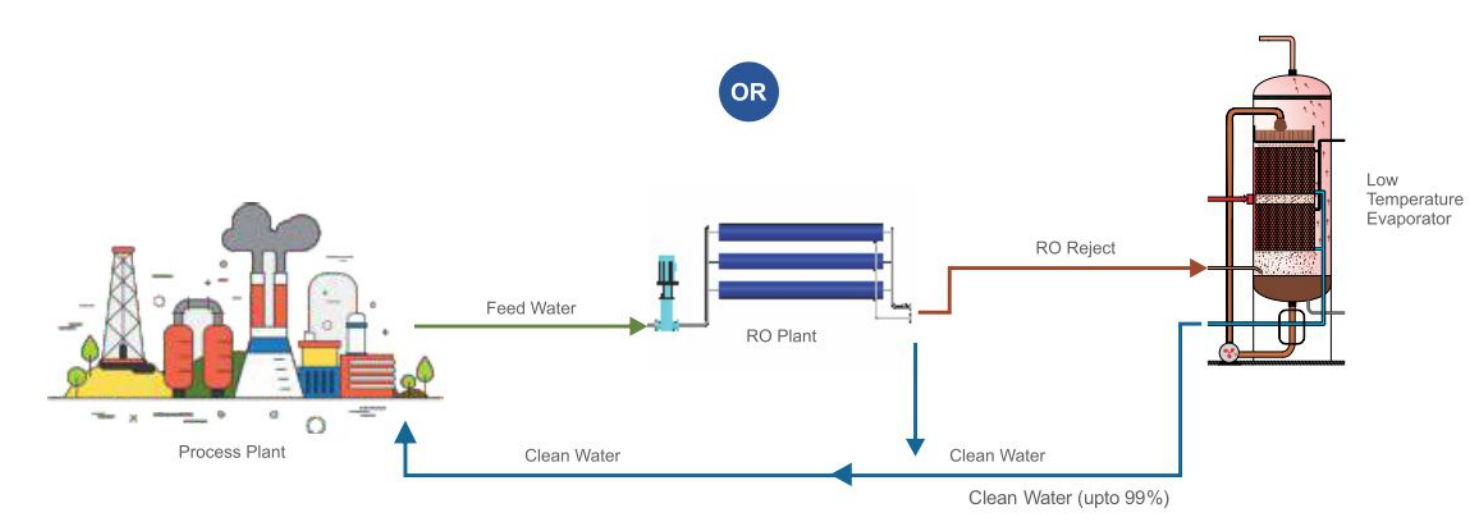

Low Temperature Evaporator is an innovative system to recover clean water along with concentrated solution separately, by processing industrial and domestic wastewater of wide variety. Its used to concentrate various fluids by evaporating excess water upto 99% depending on Boiling Point Elevation (BPE) of fluid. All excess water is recovered as clean water or condensate separately along with concentrated fluid.

Low Temperature Evaporator is an integrated module comprising Plate Heat Exchanger, Vacuum and Mechanical Vapor Compression/Recompression.

-

Mechanical Vapour Compression/ Recompression recycles steam required for evaporation eliminates continuous use of external heating source during operation.

-

High pressure compressed vapors enter in the evaporator calandria, which evaporates excess water and generates low pressure vapors.

-

Low pressure vapors are then compressed by Mechanical Vapour Compression/ Recompression and recycled in Low Temperature Evaporator resulting in a highly energy efficientprocess.

Usage

Services

JSC offers high quality turnkey projects & services. We provide comprehensive solutions to our valued customers with Project Management Systems of international standards and know-how involving the plant data collection, monitoring & controlling of project using cutting edge Softwares, Project Management & Scheduling, Resource Planning, Erection & Commissioning, Preparation of Detailed Start-up and Validation Schedule, Development of Plant Automation and Controlling, Trouble Shooting, Post Analysis of the Project Parameters after Commissioning etc.

Solutions For Sugar Industry

MODERNSUGAR PLANT

JSC is poneered in accomplishing energy efficient products and innovative technologies for substantial reduction in energy consumption n process and allied industries. JSC isfocused on (re}designing and engineering of processes, equipment design manufacturing along with their complete automation ensuring highest energy efficiencies and integrated cost-effective solutions. The steam consumption ofsugarindustry hasbeen achieved upto 30-34% on cane using JSC’ innovative technologies, equipment and solutions. The power (40kW/Ton) consumption has teen reduced upto 22-24 KW/Ton of cane and factory has been managed to operate with Zero Fresh Water requirement

Our expertise:

- Turkey plantistallation for sugar &sugar refinery

- Boing house equipment design, engineering, manufacturer and supplier

- Specialzed in Evaporation, Crystallization, Sugar Refining Cooling & Condensing System

- Modern process house layout design with 60-70% bss civil work and 40% lessfoot print area

- Lowest steam consumption and higher power generation & export

- Highest bagasse saving and higher qually & high yield production

- Compete ndustrialand plantautomation

- Projectmanagement consultancy services

- Detalkd process design and engineering Feasibility Sudy/Detailed Project Report OPR)

- Customized solution and technical support

Solutions For Jaggery Industry

FEATURES OF MODERN JAGGERY UNIT

- Boiler free jaggery unit

- Zero emissions

- Zerointake water

- 100% bagasse saving

- Improved clarification technique

- Innovative evaporation by MVC technology High yield jaggery production

- Energy efficient modernized and cost effective

- Low capital expenditure

- Highly economical in recurring operational cost

- Compact, Portable and Robust

- Offers scope to multiply revenue centres