Projects

Sugar Consultancy Clients

Balrampur Chini Mills Ltd,

Kumbhi Unit

Expansion from 8500 TCD to 10500 TCD in Process House. Total Study the existing system, Equipment Bottle necks, DPR, Preparation of Technical Specifications, Orders releasing, Drawings Approval and execution of Expansion project etc

Balrampur Chini Mills Ltd,

Balrampur Unit

Plant stabilisation to 12000 TCD with refinery Total Study the existing system, Equipment Bottle necks, DPR, Preparation of Technical Specifications, Orders releasing, Drawings Approval and execution of works by providing drawings

Kon Tum Sugar Joint stock Company,

Kon Tum Vietnam

Identification of Bottlenecks and increase crushing capacity to 2500 TCD in 23-24 season. Plant stabilisation Process Performance improvement (Sugar Colour, FM Pty) and energy saving are the main targets.

Chodavaram Co-operative sugar Mills,

Govada, A.P, India

Factory crushing stabilisation to 4000 TCD and rearrangement of Evaporators to reduce steam consumption.

KM SUGAR MILLS,

Moti Nagar

Plant expanded to 10000 TCD with upgradation of Technology to Refinery. Plant stabilisation and identification of short falls.

Himalaya Sugar Mills Ltd,

Nepal

Consultancy for Plant stabilisation and energy Saving

Everest Sugar & Chemical Industries,

Nepal

Consultancy for Plant stabilisation and energy Saving

Equipment Supply / Projects:

Everest Sugar & Chemical Industries,

Nepal

Direct Contact Heaters for Defecated Juice & Clear Juice

Himalaya Sugar Mills Ltd,

Nepal

Direct Contact Heaters for Defecated Juice & Clear Juice

Chodavaram Co-operative sugar Mills Ltd,

Govada, A.P India

Direct Contact Heaters for Clear Juice & Evaporator Bodies

HDJ BAYAWAN AGRI- VENTURE CORP.

Philippines

Materials for Sugar Mill

4.BARAMATI AGRO (P) Ltd, Baramati,

India

Deep Bed Filter

Syrup Clarification system

Himalaya Sugar Mills Ltd,

Nepal

Consultancy for Plant stabilisation and energy Saving

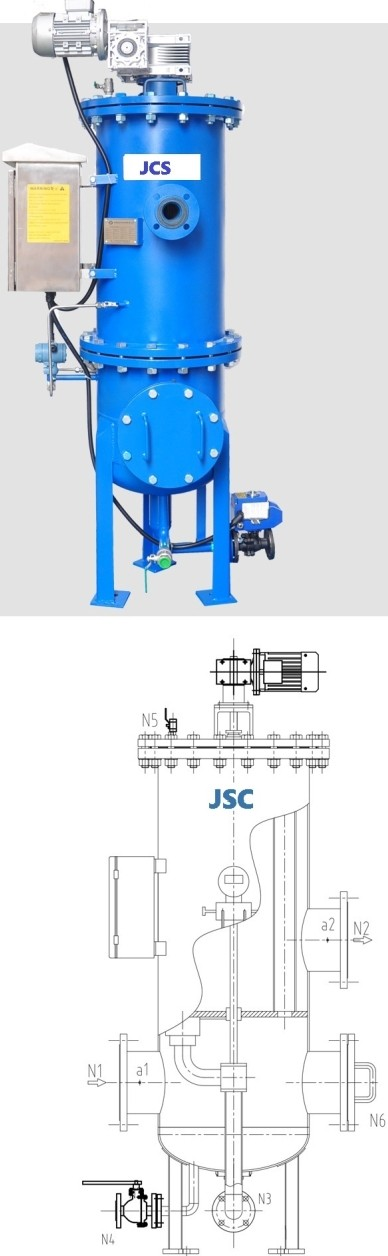

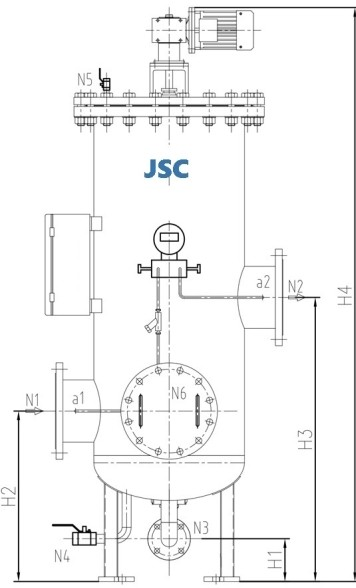

Focus on advanced filtration equipment manufacturer.

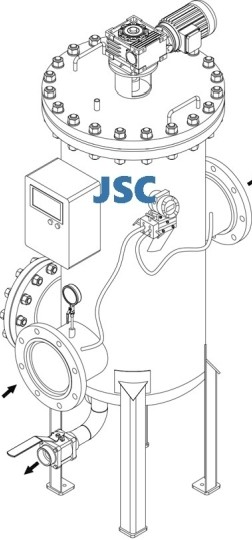

MAF-BW SERIES AUTOMATIC BACKWASH FILTER

| Single Capacity | 1-8000 M3/H, (Paralleled structure is available) |

| Application | Water & Low viscosity liquids ( <40 CP) |

| Body Material | CS, SS304, SS316L Duplex SS2205/2507 |

| Contro Box | IP54 I Ex , (Touch screen customization) |

| Desige Pressure | Default 0-1.6Mpa (Higher pressure is customized |

| Design Temperature | Default -10-80 °C (Depened on the sealing) |

| Filter Element | V-slot Mesh |

| Micron Rate | 30-3000um |

| Cleaning Control | Time/PD,Manul (RS485 Remote is available) |

| Cleaning Type | backwashing one by one |

| Model | Filtration area (M2) | Hl(mm) | H2(mm) | H3(mm) | H4(mm) | Flowrate(M3/H) | lnlet/Outlet(DN) | Drain(DN) |

| BW-300 | 0.83 | 150 | 450 | 850 | 1850 | 80 | 100 | 25 |

| BW-400 | 1.31 | 150 | 550 | 950 | 1900 | 190 | 150 | 40 |

| BW-500 | 1.80 | 150 | 650 | 1050 | 2000 | 330 | 200 | 40 |

| BW-600 | 2.80 | 150 | 700 | 1300 | 2450 | 520 | 250 | 50 |

| BW-700- S | 3.20 | 150 | 750 | 1300 | 2600 | 760 | 300 | 50 |

| BW-700-L | <; 1/ | 1SO | 7SO | pnn | '"nn | 1mn | >< n | so |

| BW-800-S | 4.00 | 150 | 850 | 1350 | 2650 | 1030 | 350 | 50 |

| R\M_onn_ 1 | <; 77 | ?nn | 8SO | p< n | '"| nso |

Ann |

f;<; |

|

| BW-900 | 6.76 | 200 | 900 | 1600 | 2760 | 1700 | 450 | 80 |

| BW-1000 | 8.67 | 200 | 900 | 1600 | 3000 | 2200 | 500 | 80 |

Note: the above flow data is the reference water nozzle processmg capacity, different v1scos1ty fluid, different flow rate, different accuracy, processing capacity will be different

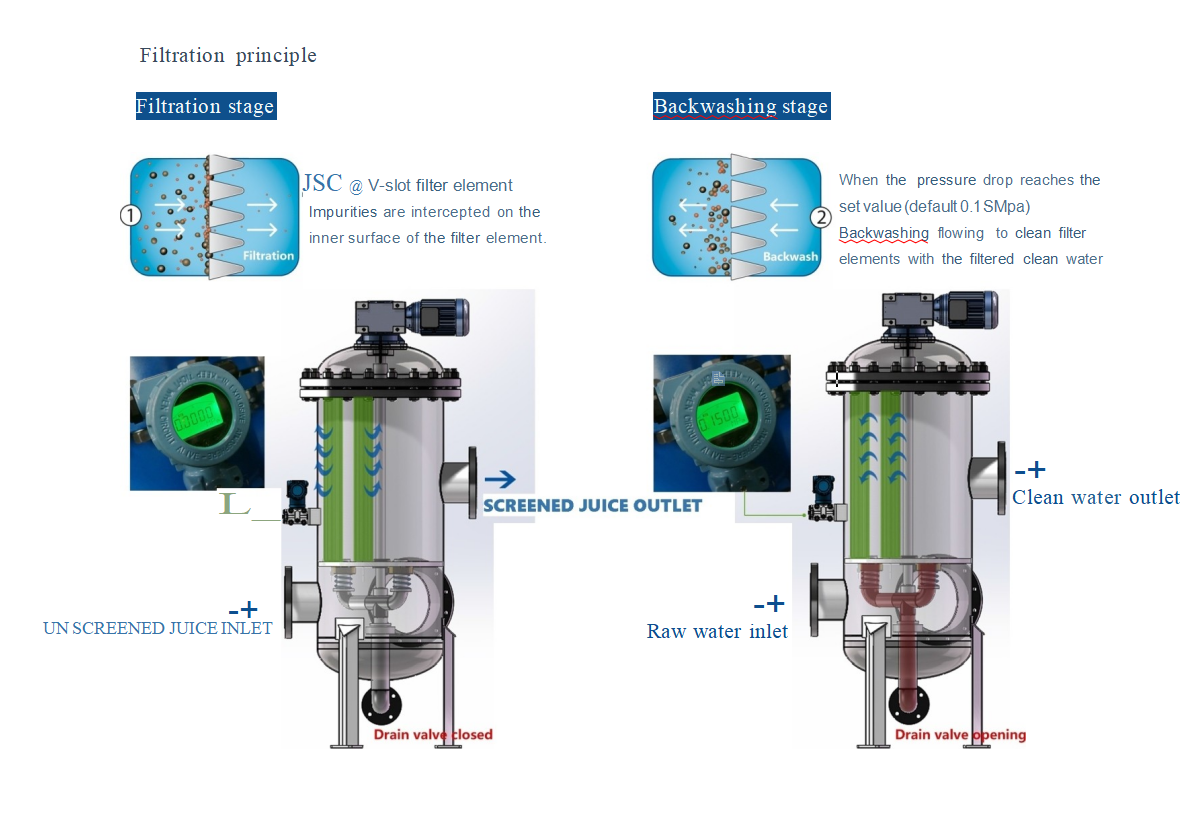

1. Filtering stage

During the filtration stage, solids are obstructed and deposited on the smooth surface of the filter element, forming a filter cake. Filter cakes can block smaller solid particles. The extremely small solid shell that has not been intercepted passes through V-shaped gaps

2. Backwashing stage

The filtered clean water (gas/high-pressure water) flows in reverse, and at the moment when the drain valve opening, Under the action of pressure difference, reverse water flowing will remove the filter cake and solids from the surface of the filter elements.

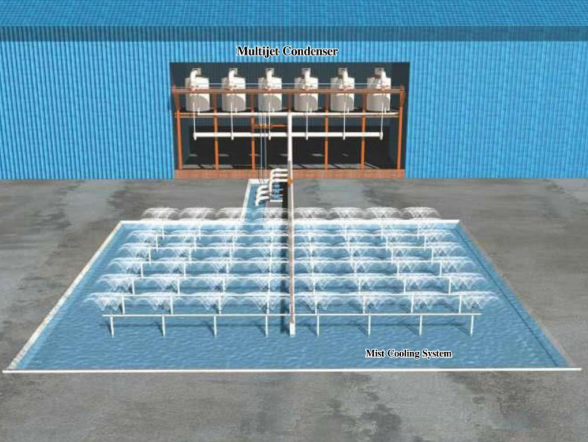

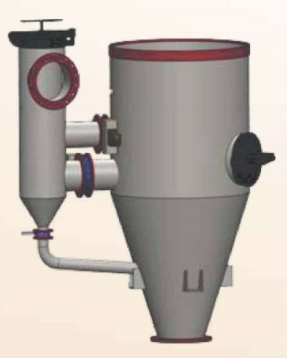

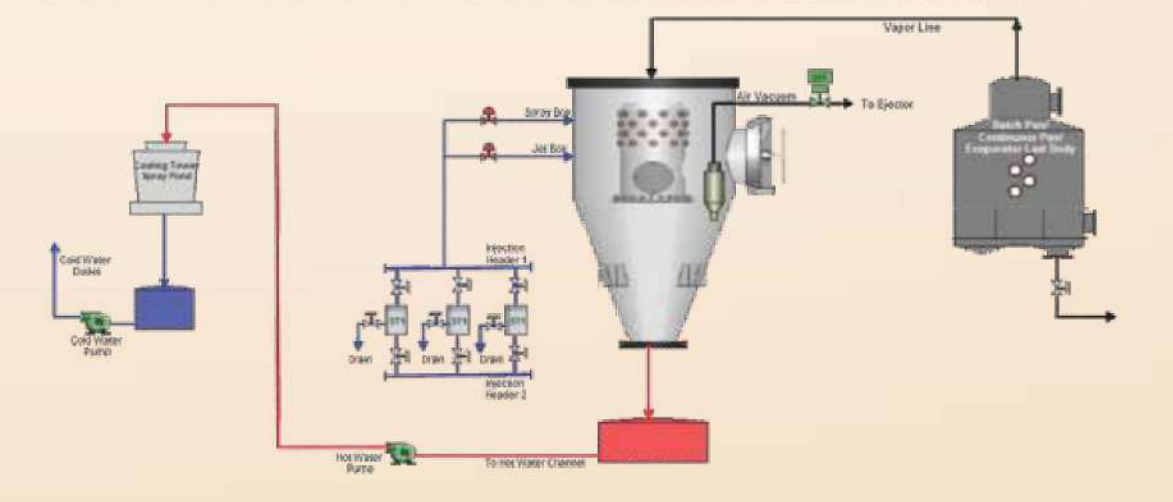

Complete Condensing System

Condenser

Condenser is an apparatus which accepts a vapour stream and converts it int liquid using heat transfer and/or compression. The Vapour or steam 10 he condensed mixes withthe cooling water and the temperature of the condensate and the cooling war is the same when leaving the condenser. In this condenser the cold water is drawn up in the condenser shell from the spray pond due (© the. vacuum head created in the shell. The shell is arranged with the spray box to break up water into small jets. The Steam and Non- Condensate Gas enter a the shell. Thus the steam gets condensed and the air ascends up and cools down.

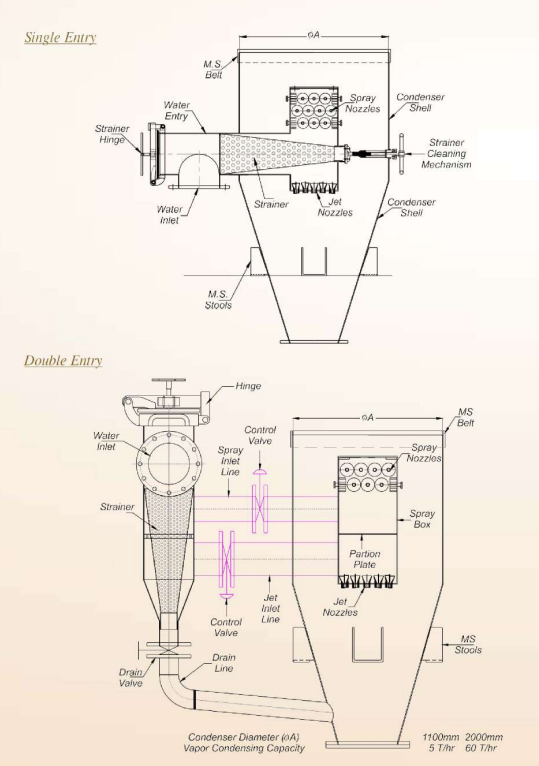

Multi-Jet Condensers

Muli jet condensers absorb vapors during o-current mixing with water droplets. Non condensable gases. are evacuated by the water jes without the need of any extra device ar energy. Spray Nozzles primar condense water vapors and Jet nozzles increase. momentum of water flow in the wilpipe. As it moves rapidly down the ailpipe, multiphase flow of heated water and air bubbles is compressed. Effective use: of cold water and residual heat of vapors makes the combination most energy efficientsystem.

Main Advantages

- Rapid generation of intial vacuum.

- Co-current design minimizes pressure losses,

- No separate vacuum pump.

- Simple and easy maintenance.

- Smooth operation even in hot and humid conditions.

- Low power consumption.

- Automated condensers.

In manual condensers, vapors and air load fluctuates with syrup level in Pan. steam pressure, plant utilization and leakage levels. This results into consumption of large amount of water and power in manual condensers. Thus. water flow control is required to maintain correct vacuum and. reduce consumption of water and power. Manual condensers are, therefore, designed for extreme conditions of vapor load, inlet water temperature and air leakage.

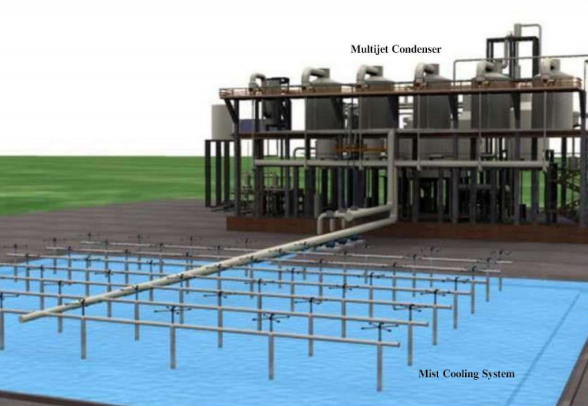

Spray Pond/Mist Cooling System

Spray Ponds or Mist Cooling System from JSC's is an innovative application of modern materials, designs and architecture to a century old concept. Iti, specifically suitable for small and medium sized factories for example, in rural areas that have sufficient open space for ponds. Normal wind and upward draft from warm air creates positive cooling effect on sprayed water. Thus, Spray Ponds save energy, otherwise needed to run cooling fans.

JSC's, so far designed more than one hundred mist cooling system that are operating across the world. It offers complete solutions for a variety of applications. Spray Ponds/mist cooling system can cool water within 8°C of Wet Bulb temperature and provide cooling from 10 to 20°C. It uses Stainless Steel, ABS and PVC Thermo- Plastics combination obtain long and maintenance free life of system.

Multi Jet Condenser with Nozzle Governing

JSC's Multi jet Condenser with Nozzle Governing System ensures best condenser efficiency with fluctuating vapor or NCG/Air load at constant vacuum. It consists of actuator fitted jet and spray nozzles. This actuator is a spring loaded water cylinder. Nozzles are categorized into stages, where the number of operational stages depends upon the system requirement.

The system has following features:

- Hydro dynamically designed nozzles made of engineering thermoplastics.

- Optimally sized tail pipes for high air evacuation capacity.

- Manhole and water inlet, with a hinge type door for convenient and quick maintenance.

- Strainer with an online cleaning mechanism.

- Change over manual mode in case of power failure.

The system has following features:

- External ejection system for additional air removal.

- Inbuilt air cooler for cooling air during ejector support.

- Highest possible outlet water temperature.

- Individual control of desired vacuum for Evaporators and Pans.

- Clear indications in case of vacuum failure.

- Customized solution as per site requirement.

- Best efficiency even at 25% of designed load.

Multi-Jet Condensers with Control Valves

JSC's Multi-Jet Condenser is a customized design introduced recently for more robust applications. Water flow to condensers is controlled by separate control valves for jet and spray nozzles. Nozzles are, particularly designed for least maintenance without compromisina performance

- Quick & easy maintenance.

- Centralized Online Strainer Cleanin Mechanism

- Handy design where frequent cleaning is required

Multi Entry Control Valve Based Cooling & Condensing System

Complete Condensing System

Our latest design of complete condensing system with "Zero Depth Design" is most efficient design beating

JSC's is a leader in complete condensing system with more than 1000 installation across the world

With R&D being the core, JSC's uses the best combination of designs(i.e. Multjet condenser + mist cooling system),Meterial manufacturing company and automation system to engineer most efficient complete condensig system.

All the convenient cooling system, We have designed the automated completed cooling and condensing system

Advantages

- Rapid generation of initial vacuum

- Constant vacuum

- Lower water vapour ratio

- Optimum waste quantity

- Maximum inlet-outlet water temperature difference

- Least power consumption

- Best efficiency even at 25% of designed load

- Provision for variable set point during operation.